or use Browser's Back Arrow

How I Built My Window Counterweight System

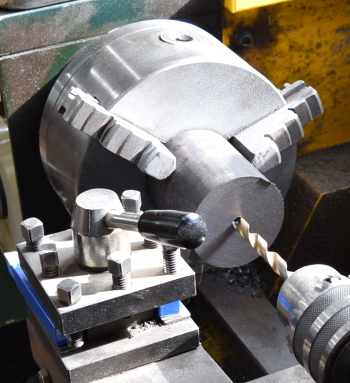

To start, the window counterweights were made by cutting two 3¼" chunks from a 2½" steel bar.

The window was lowered onto a bathroom scale where it weighed about 10 pounds, so we want the counterweights to weigh less than that so the window will remain naturally closed. Using a Steel Bar Weight Calculator (many on the internet) it shows that a 2½" steel bar weighs 1.4 pounds per inch. That's 4½ pounds for 3¼" and 9 pounds for both weights giving a good balance with 1 pound of actual window weight.

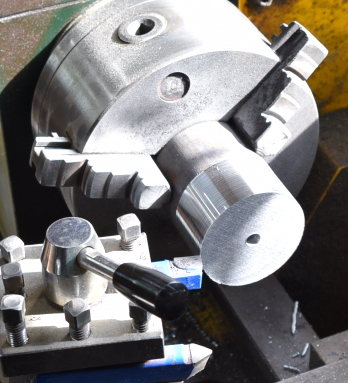

Each weight was faced to remove the mill scale caused by hot rolling.

I'll be using 3/8" NC (National Coarse) bolts so I drilled a 21/64" hole into each weight.

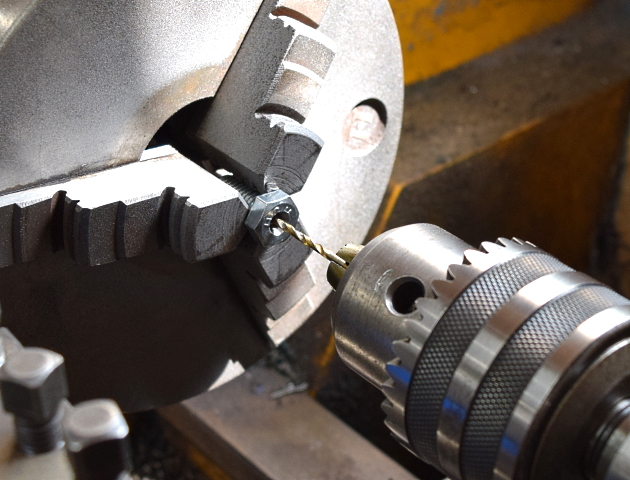

The 3/8"x1" bolts were "Centre Drilled", enough to leave the countersink, then drilled through with a 3/32" bit (below) to accept the 3/32" wire rope.

The holes were threaded with a 3/8"x16 TPI tapered machine tap, so the 3/8" bolts were also tapered at the ends, to bottom into the wire rope flare.

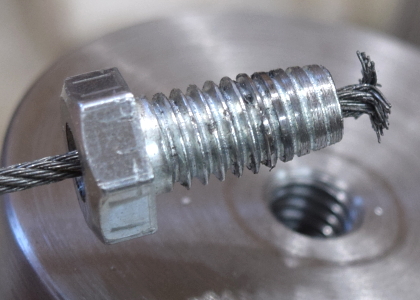

Instead of swaging a loop at one end and attaching it to an eye bolt, I wanted to try something else. A test cable was pushed through the drilled out bolt and the ends were flared with a small screwdriver.

The weights were hung in the greenhouse (using longer 3/8" bolts) and painted with the leftover paint from the Pressure Washer bumper handle. (see Advanced Tips & Tricks page)

Everything is ready for assembly. The wire ropes were swaged at one end with aluminum "hour glass" sleeves and my homebuilt swaging tool. Then the swaged end was screwed into the window's top corner, leaving some play, and the other end was run through the swivel pulley which was attached to the eye hooks. Then the end was pushed through the 3/8" bolt and flared as above, then screwed into the red weight, and the same was done to the other side. It lifts much more easily than before. While leaning over the shelves, it now lifts as easily with one finger as it did before with two hands, yet stays well seated when down.

The tapered bolt was tightly screwed into the weight, tested to over 100 pounds and unscrewed.

Note: the Greenhouse Button takes you back to the top of the page. The Back Arrow takes you back to where you were.