The original mock-up (middle pic) is held together by magnets, clamps and gravity. The bender worked well, but after welding it all together (left pic), I discovered that the detachable handlebars (middle pic) were too far back, so I did a quick mod (right pic) using some leftover wheelchair sections.

NOTES:

- The wheelchair armrests become the front bumpers in the above left girl pic - shown better here -

- The above right two pics show the "quick change, anti-tip" training wheels - from the wheelchair.

- The shopping basket is a Supercycle bicycle basket from Canadian Tire.

- The handlebars and grips fold down - from the wheelchair.

- The finger controlled smooth joystick ball was "plasti-dipped" in liquid rubber and is now thumb operated.

- The joystick controller is clamped to the right handlebar and can be easily moved to the left handlebar.

- The originally horizontal motors, are now vertical.

- The machine adds 4 inches to the rider's height, making it an easier "high shelf reach" for many shoppers.

- The large, normally rear drive wheels are now in the front and the front casters are now in the rear.

- To reverse the forward/backward direction, I just swapped the normal location of the two drive wheels.

Princess Auto in Kingston, Ontario, August 2013

Home Hardware in Napanee, Ontario, July 2015

So I bought a cheap foldable power wheelchair and disassembled it. Then I designed a whole new frame to stand on, which would accept the wheelchair motors, wheels and welded tubing.

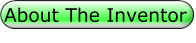

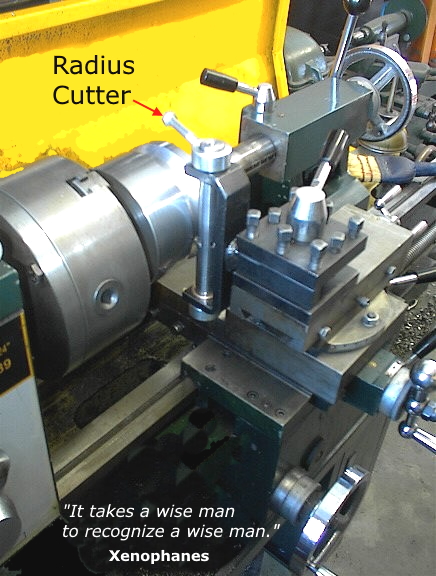

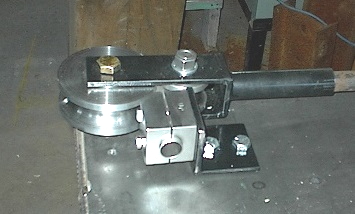

I did not own a 1" tubing bender so I had to design and build my own. The above picture shows the radius cutting tool I built to cut a perfect 1/2" radius groove in the 6" round block of steel, then I cut another 1/2" radius groove in a 2.5" round steel block. To drill a perfect 90°, 5/8" hole in the workbench, I positioned my drill press in the right photo (note sand bag damping and floor jack locking) and installed my bender below.

After watching its assembly on a "How It's Made" TV show, I was impressed by the genius of Dean Kamen whose means and ability were beyond this poor backyard inventor. Also, it did not appear that his quick, slick (and accident prone) machine was designed for mobility impaired "little old ladies". A wheelchair was more my mother's "speed" but she resisted that thought as she (like many) did not wish to be seen as (and therefore feel) "crippled". Besides, she could stand and move about a room. She just needed something to increase her range. That's when the idea hit me.

Why not "re-invent the wheel" chair?

"The true difficulty is building the machine that makes the machine."

Elon Musk

Above pic and below right pic were taken inside, where -

"The camera flash made the normally inconspicuous conspicuity tape conspicuous."

In the following quote, Mark Twain compares the Mergenthaler type setting machine to the complex Paige Compositor, into which he had invested, and eventually lost, his life savings. At this time both machines were in the middle stages of experimental development.

"The Mergenthaler, although slower, was simpler, less expensive and occupied less room. There was not so much about it to get out of order and these were immense advantages." Mark Twain (1890)

After noticing the mobility problems my late mother had in her eighties with two artificial knees and an artificial hip, I began to think about personal transports.

"Mother is the Necessity of my Invention."

There are many high tech personal transport marvels out there, including the grandfather of them all, the Segway, introduced in 2001.

Below are the words I typed into GROK, - then four separate, distinct and different images were generated in 1024 X 768 format. I then resized them to fit the preferred space. When text is enclosed in quotes, it tries to place it into the image, but it often has some difficulty, as shown here. Of course this is not a picture of the actual Paige Compositor, - but Grok is still developing.

To get Grok to reply with an image, just start your text with words like, Image, Paint, Draw, Cartoon, Picture, Anime, Watercolor, Sketch, etc.

Draw, Mark Twain, smiling, pointing at a massive, mechanically complicated, gears, levers, with the text "Paige Compositor" on a huge type setting printing press, in a victorian factory

These other two images were created using similar text. It took about 20 seconds to generate four images.

HARTFORD, Jan. 5, 1889.

DEAR ORION,--At 12.20 this afternoon a line of movable types was spaced and justified by machinery, for the first time in the history of the

world! And I was there to see. It was done automatically--instantly--

perfectly. This is indeed the first line of movable types that ever was

perfectly spaced and perfectly justified on this earth.

This was the last function that remained to be tested--and so by long

odds the most amazing and extraordinary invention ever born of the brain of man stands completed and perfect. Livy is down stairs celebrating.

All the witnesses made written record of the immense historical birth--

the first justification of a line of movable type by machinery--and also

set down the hour and the minute. Nobody had drank anything, and yet

everybody seemed drunk. Well-dizzy, stupefied, stunned.

All the other wonderful inventions of the human brain sink pretty nearly

into commonplace contrasted with this awful mechanical miracle.

Telephones, telegraphs, locomotives, cotton gins, sewing machines,

Babbage calculators, jacquard looms, perfecting presses, Arkwright's

frames--all mere toys, simplicities! The Paige Compositor marches alone

and far in the lead of human inventions.

In two or three weeks we shall work the stiffness out of her joints and

have her performing as smoothly and softly as human muscles, and then we shall speak out the big secret and let the world come and gaze.

Return me this letter when you have read it.

SAM.

DEAR MR. HALL,— ... I hope the machine will be finished this month; but it took me four years and cost me $100,000 to finish the other machine after it was apparently entirely complete and setting type like a house-afire.

I wonder what they call “finished.” After it is absolutely perfect it can't go into a printing office until it has had a month's wear, running night and day, to get the bearings smooth, I judge.

August 14, 1893

I strongly advise that every penny that comes in shall be applied to paying off debts.

What I am mainly hoping for, is to save my royalties. If they come into danger I hope you will cable me, so that I can come over and try to save them, for if they go I am a beggar.

NOTE: Mark Twain was the pen name for Samuel Langhorne Clemens. He was called Sam by his family and close friends. His brother was Orion and his wife, Olivia Langdon, was called Livy.

NOTE: I have paraphrased the original letter, which was in much greater detail.