Special Features of My Sawmill

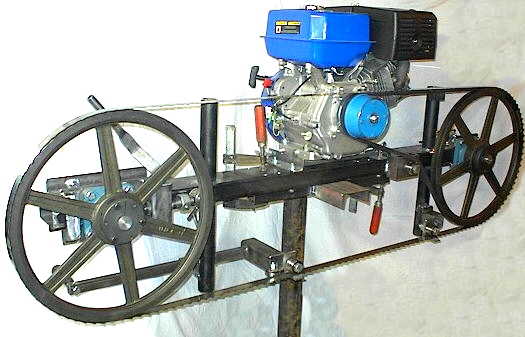

19" Band Wheels Independent tests have shown that the blades we use will not suffer metal fatigue (before their cutting life is over) if the band wheels are greater than 18", therefore our band wheels are 19" in diameter. My experience has concurred with these tests. Between several machines and after years of sawing, the blades always wear out before they show any signs of metal fatigue or crazing.

Motor directly drives the band wheel This is the most efficient design and it saves the cost of an additional drive pulley. The full power of the motor is transmitted to the blade, cutting more wood with less fuel. Putting the motor pulley directly between the band wheels enables a narrower carriage, allowing a longer log to be cut for any given bed length. It also allows the motor pulley and drive belt to support the upper part of the blade in the center, preventing excessive blade vibration.

Anti-Vibration Carriage Almost all of the motor vibration is absorbed by the unique "loose fit" vertical guide tubes and "cable suspension" design.

Multi Purpose Vertical Guide Tubes - also hold the blade guides and the unique "lifting rollers"

Blade tightens and loosens instantly - with the simple press of a lever. The blade and even the drive belt can be changed in seconds without tools or removing the guards or opening (removing) guard doors etc.. The lever also allows the blade to be instantly slackened when the mill isn't being used.

The tension for some other band sawmill blades is around 2000 pounds and because of the time and tools required, most sawmill owners keep this tension on all the time which can lead to blade stretching and premature failure.

The Bed Frame can be any length up to 24' and this mill cuts a log just two feet shorter than the bed but with track extensions of 1 foot at each end, the mill will cut a 24' log. Of course bed extensions can be added to cut a log of any length. (see Basic Sawmill Questions)

The Powerhead and Bed both use the "Kingpost Truss" design for lightweight strength. (see Basic Questions)

The Powerhead is quickly, easily and accurately raised and lowered in the carriage without any expensive or cumbersome:

(threaded rods) (springs) (gears) (belts and pulleys) (chains and sprockets) (winches) (ratchets) (jacks) (garage door openers) (electric motors) or (hydraulics)

The Height Gauge moves up and down with the power head, so that the marker line is always at "eye" level.

All Position Dogs can be clamped anywhere on the log with just a quick push of a lever. They move up and down as well as left and right and don't leave a piercing "bite hole" in the log or sawn cant. No cranking a screw into the log, so it can be clamped (or released) in a second.

Industrial Centrifugal Clutch featuring ball bearings, a cast iron drum and four automotive brake pad shoes. Using a centrifugal clutch saves building additional blade engagement systems where there is belt slippage and wear during blade start-up, so the drive belt lasts much longer.

(see Advanced Sawmill Questions)

Plus many more, including: trailer towing package, taper compensator, 5 gallon UV protected visible coolant bottle, umbrella mounts, shake and bevel siding wedges, dual carriage lockdown positions, etc..

"Imagination is more important than knowledge."

Albert Einstein

Blade Guards are rounded "non clogging", "Pittsburgh Seamed" scratch resistant galvanized steel which, of course, could be painted if desired.

Bed "Trailer" Wheels remove in seconds and have three height positions. This helps to get a level position when towing on the road and to use the highest position for clearance when towing over rough terrain.

Trailer Towing Tongues - user selectable - the 2" has four height positions and the 3" has two positions. Both are easily removable (and interchangeable).